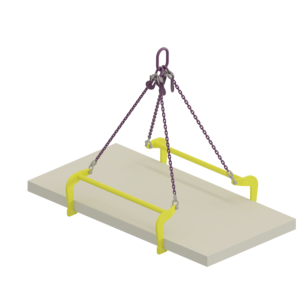

The IPU10 vertical lifting clamp is used for lifting, turning, moving or vertical transfer of sheet, plates, or fabrications from horizontal to vertical and down to horizontal (180°) as needed. The hinged hoisting eye ( a.k.a. universal eye ) allows for the clamp to place and lift the load from any direction, or with a multiple leg sling without side-loading the clamp. Available in a variety of models:

- IPU10 - Standard clamp for materials with a surface hardness to 363HV10 (345 HB).

- IPU10J - Larger jaw opening.

- IPU10S - For use with Stainless Steel material.

- IPU10H - For use with materials with a surface hardness to 472HV10 (450 HB).

Features:

- Available in capacities of 0.5 thru 30 metric tons

- Higher Working Load Limits are available upon request.

- Wide variety of jaw openings available: 0 to 155 mm.

- Welded alloy steel body for strength and smaller size. Forged alloy components, where required.

- Individually Proof Tested to 2 times the Working Load Limit with certification.

- User manual and test certificate included with each clamp.

- Full 180° turning range for material transfer, turning or moving.

- Lock open, lock closed ability with latch for pretension on material and then release of material.

- For use with materials with surface hardness to 279HV10, only 5% min WLL is needed.

- Maintenance and repair kits are available.

- All sizes are RFID EQUIPPED.

- Material: Alloy steel.

- Marking: According to standard, CE-marked

- Standard: EN 13155

- Warning: A minimum load of 10% of the WLL is required. Except for WLL 500 KG which requires a minimum load of 5% of WLL.

- Safety factor: 4:1